Navigating Luxury Prefab Homes for Sale: Key Features, Costs, and Market Trends

Luxury prefab housing has moved from niche to notable, offering high design, precision manufacturing, and faster timelines compared with conventional custom builds. This guide explains how upscale modular and panelized homes achieve their finish quality, what influences total project cost, and how current market trends are shaping choices in the United States.

Luxury prefab homes combine factory precision with architectural ambition. Instead of compromising on materials or design, many manufacturers now deliver high performance shells, refined interiors, and smart systems while shortening schedules and reducing weather related risk. For buyers evaluating options in the United States, understanding definitions, cost drivers, and provider differences helps set realistic expectations.

What defines Luxury Prefab Homes for Sale

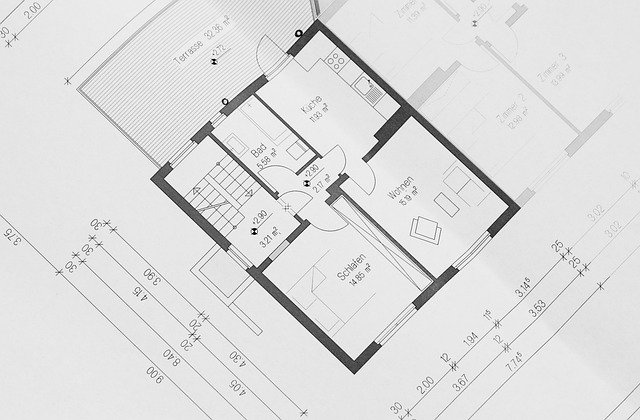

Luxury in prefab is less about sheer size and more about specification and performance. Hallmarks include engineered building envelopes with tight air sealing, premium windows, long span structural solutions, and curated finish packages. Buyers also see integrated smart home platforms, whole house air and water filtration, and flexible floor plans that optimize light and flow. Precision manufacturing brings consistent quality control, while site work and installation complete the build in your area.

Finding Affordable Luxury Prefab Homes for Sale

Affordability in the luxury segment often comes from design choices. Smaller, smarter footprints reduce cost without sacrificing experience. Standardized model lines limit custom engineering fees. Choosing mid tier finishes where they matter least and investing in kitchens, baths, and building envelope can keep budgets balanced. Early coordination on site conditions, local services, utilities, and permitting helps prevent overruns. Financing typically follows custom home norms, so speak with lenders familiar with modular or panelized construction to streamline appraisals.

Modern Luxury Prefab Homes for Sale: design and tech

Modern luxury prefab emphasizes clean lines, efficient layouts, and high performance assemblies. Many providers offer triple glazed windows in colder climates, air source heat pumps, heat recovery ventilation, and solar readiness. Factory built components support tight tolerances that improve energy efficiency and indoor comfort. Exterior options like fiber cement, engineered wood, or metal panels deliver durable low maintenance facades, while interior systems are pre planned for smooth integration of lighting, audio, and security.

Costs explained and how to plan the budget

Total project cost blends the home itself, transportation, crane set, foundation, site utilities, permits, design work, and local labor. For upscale specifications, many buyers plan for a completed cost that is competitive with custom site built homes of similar quality. Location, seismic or wind requirements, and driveway or grading needs can shift budgets significantly. Request itemized estimates that separate factory scope from site scope and include contingencies for unknowns such as rock excavation or utility upgrades.

| Product or service | Provider | Cost estimation |

|---|---|---|

| Turnkey luxury prefab home, total project estimate | Dvele | Approximately 400 to 700 dollars per square foot, depending on location, finishes, and site scope |

| Turnkey luxury prefab home, total project estimate | Plant Prefab | Approximately 350 to 650 dollars per square foot, depending on model complexity and site conditions |

| Turnkey luxury prefab home, total project estimate | Method Homes | Approximately 350 to 600 dollars per square foot, varying by climate zone and finish level |

| Turnkey luxury prefab home, total project estimate | Stillwater Dwellings | Approximately 400 to 700 dollars per square foot, influenced by customization and regional labor |

Prices, rates, or cost estimates mentioned in this article are based on the latest available information but may change over time. Independent research is advised before making financial decisions.

Market trends shaping the category

Demand for precision built housing has grown alongside labor shortages and rising on site construction costs. Buyers value shorter build durations, reduced waste, and predictable quality. Energy codes are tightening, pushing more manufacturers to offer higher performance shells and electrification ready systems. At the same time, interest in resilient design has increased, from non combustible exterior cladding in fire prone regions to enhanced water management in coastal zones. Supply chain volatility continues to affect lead times, so early lock in of models and selections can help stabilize schedules.

How to evaluate models and providers

Compare structural systems, energy targets, and scope boundaries. Ask which elements are completed in factory versus on site and who manages local trades. Review sample contracts and warranty coverage for both the manufacturer and general contractor in your area. Verify transport logistics, crane access, and foundation design early. Finally, request references for projects completed under similar climate and code conditions to assess real world performance and schedule certainty.

Conclusion

Luxury prefab homes aim to deliver architectural quality with process reliability. Clarity on specifications, scope split, and site conditions is essential for accurate budgeting. By pairing modern design and high performance assemblies with disciplined planning, buyers can align cost, timeline, and long term comfort while navigating a growing set of reputable providers in the United States.