What is an insulated prefabricated house and how much does it cost?

Insulated prefabricated houses represent a modern approach to homebuilding that combines factory construction with enhanced energy efficiency. These structures are built off-site in controlled environments, then transported and assembled on your property. The insulation component refers to advanced thermal barriers integrated during manufacturing, creating homes that maintain comfortable temperatures year-round while reducing energy consumption. Understanding the costs, benefits, and available options helps potential homeowners make informed decisions about this increasingly popular housing solution.

Insulated prefabricated houses offer a compelling alternative to traditional construction methods, combining efficiency with sustainability. These homes are manufactured in climate-controlled facilities where precision assembly and quality materials create structures designed for long-term durability and energy performance.

Understanding 2 & 3 Bedroom Custom Built Homes

Custom built prefabricated homes in two and three-bedroom configurations provide flexibility for growing families and diverse living needs. The customization process allows homeowners to select floor plans, interior finishes, and exterior materials while maintaining the cost advantages of factory construction. These homes typically feature open-concept living areas, modern kitchens, and efficient use of space that maximizes comfort within compact footprints.

The construction timeline for custom prefab homes ranges from 8 to 16 weeks, significantly faster than traditional building methods. Quality control measures during factory assembly ensure consistent standards and reduce weather-related delays common in on-site construction.

Exploring 2025 Luxury Prefab Bungalows with Solar Panels

Luxury prefabricated bungalows represent the premium segment of the prefab market, incorporating high-end materials and advanced technologies. Solar panel integration has become increasingly standard in luxury models, providing renewable energy generation and long-term utility savings. These homes often feature premium appliances, hardwood flooring, granite countertops, and smart home automation systems.

The single-story design of bungalows appeals to buyers seeking accessibility and aging-in-place features. Large windows, covered porches, and open floor plans create spacious living environments despite compact exterior dimensions. Energy-efficient systems combined with solar panels can achieve net-zero energy consumption in optimal conditions.

Discovering 6 Great Small Prefab Homes

Small prefabricated homes address the growing demand for affordable, sustainable housing options. These compact designs typically range from 400 to 1,200 square feet, maximizing functionality through clever storage solutions and multi-purpose spaces. Popular small prefab models include tiny homes on wheels, accessory dwelling units, and compact family homes.

Design innovations in small prefab homes include fold-down furniture, built-in storage systems, and convertible living spaces that adapt to different daily activities. Despite their size, these homes often include full kitchens, comfortable sleeping areas, and modern bathrooms that rival larger traditional homes.

Insulation Technology and Energy Efficiency

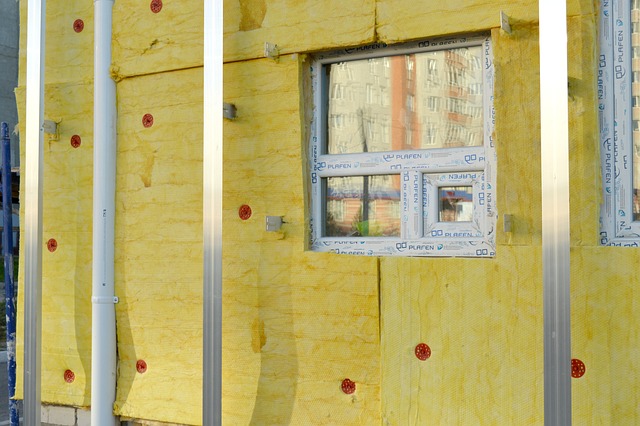

Advanced insulation systems in prefabricated homes utilize materials like spray foam, rigid foam boards, and high-performance fiberglass to create superior thermal barriers. Factory installation allows for precise application and elimination of thermal bridges that commonly occur in site-built construction. Many prefab homes achieve R-values exceeding traditional construction standards.

Energy efficiency features extend beyond insulation to include high-performance windows, advanced HVAC systems, and integrated air sealing. These components work together to create homes that consume 30-50% less energy than conventional construction, resulting in substantial long-term savings on utility bills.

| Home Type | Provider | Size Range | Cost Estimation |

|---|---|---|---|

| 2-Bedroom Custom | Clayton Homes | 800-1,200 sq ft | $80,000-$150,000 |

| 3-Bedroom Custom | Champion Homes | 1,200-1,800 sq ft | $120,000-$220,000 |

| Luxury Solar Bungalow | Blu Homes | 1,000-2,500 sq ft | $200,000-$400,000 |

| Small Prefab | Tumbleweed Houses | 400-800 sq ft | $50,000-$120,000 |

| Modular Home | Nationwide Homes | 1,000-3,000 sq ft | $100,000-$300,000 |

| Tiny Home | Modern Tiny Living | 200-600 sq ft | $40,000-$90,000 |

Prices, rates, or cost estimates mentioned in this article are based on the latest available information but may change over time. Independent research is advised before making financial decisions.

Installation and Site Preparation Considerations

Successful prefabricated home installation requires proper site preparation including foundation work, utility connections, and access planning. Foundation options include concrete slabs, crawl spaces, and full basements, with costs varying by region and soil conditions. Local building codes and permit requirements must be addressed before delivery and installation.

Transportation logistics play a crucial role in project planning, as oversized loads require special permits and route planning. Installation typically takes one to three days with crane assistance, followed by utility connections and final inspections. Professional installation ensures structural integrity and warranty compliance.

Insulated prefabricated houses represent a practical solution for modern housing needs, offering quality construction, energy efficiency, and cost predictability. The combination of factory precision and advanced insulation technology creates homes that perform well in diverse climates while providing comfortable, affordable living spaces. As technology continues advancing and consumer acceptance grows, prefabricated homes are becoming increasingly competitive with traditional construction methods in both quality and value.